11/28/14

I have an old (3 megapixel) Olympus camera that is now dedicated to recording the build. I keep it in the tool chest for photos such as these.

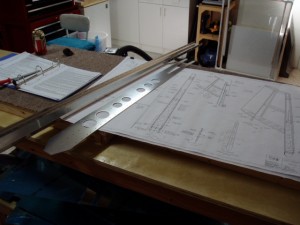

In building the Vertical Stabilizer, the first task is to smooth all edges and slightly round the corners of all the parts.

The lightening holes in the reinforcing plate are punched at the factory and have rough edges, as on the center hole shown in the photo on the right. The other two shiny holes have been finished with a Scotchbrite wheel on a drill and then a hand held Scotchbrite red pad.