Each part of the empenage seems to add a new complexity to the build. The Rudder is no exception. It does not have internal ribs like the Horizontal Stabilizer; rather it has light weight stiffeners that the builder fabricates from pre-punched angle channel stock. Tho lighter in weight than the Vertical Stabilizer the Rudder has many many more rivets.

12/05/14

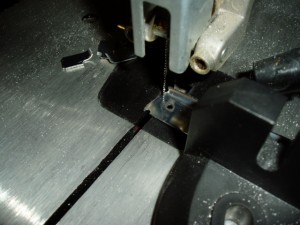

Not the best photo, but it shows a pre-punched rudder stiffener being cut on our band saw.

Not the best photo, but it shows a pre-punched rudder stiffener being cut on our band saw.

There are sixteen stiffeners.